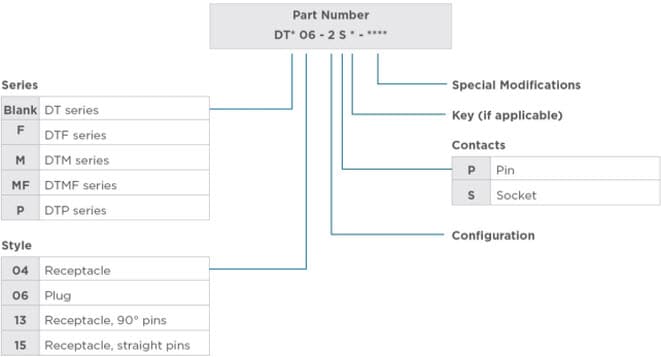

DT Family Overview

DT Series:

DEUTSCH DT Series connectors offer field proven reliability and rugged quality. The DT Series has a thermoplastic housing with in-line, printed circuit board, or flange mounts. The DT Series offers the designer the ability to use multiple size 16 contacts, each with 13 amp continuous capacity, within a single shell.

DTM Series:

DEUTSCH DTM Series connectors can be used in harsh environmental applications where reliable signal circuits are critical to operating performance. Building on the DT design strengths, the DTM connector line was developed to fill the need for lower amperage, multi- pin, inexpensive connectors. The DTM Series offers the designer the ability to use multiple size 20 contacts, each with 7.5 amp continuous capacity, within a single shell.

DTP Series:

TE's DTP Series connectors are the answer to all of your most demanding power application requirements. DTP Series connectors offer the proven reliability and quality of TE's DT Series, combined with the added flexibility of using power contacts.

DTHD Series:

DTHD connectors are single terminal connectors for heavy duty applications. The DTHD Series was developed for applications requiring a complete, environmentally sealed, single power circuit termination and can be mounted or used in-line and are available in sizes 4, 8, and 12.

SAE J1939:

SAE J1939 is a specific type of CAN that defines the communications pathways for vehicle networks. J1939 specifications were originally designed for the automotive industry, but the variety of applications using J1939 CAN systems has expanded as the use of single Engine Control Units (ECU) has become commonplace in the diesel engine market. DEUTSCH DT and DTM connector options are specifically designed to meet the J1939 standards.

DT Detector

TE Connectivity / DEUTSCH DT Detector is an extension of the

DT connector series. The 2 way plug features a transparent housing and a

wedgelock with an integrated 12 or 24V LED option. The environmentally

sealed Detector plug provides a visual confirmation of power to help

with troubleshooting, especially in areas with difficult connector

visibility and accessibility.

|

|

TE Connectivity / DEUTSCH DT Series Connectors

TE Connectivity / DEUTSCH DT Series of environmentally-sealed connectors are designed specifically for harsh environment cable to cable applications. Thermoplastic housings and silicone seals are used to allow the connector to withstand conditions of extreme temperature and moisture.

The connector may be employed with either solid-copper crimp type contacts for critical circuits or budget-minded stamped and formed contacts. The DEUTSCH DT Series general purpose connectors will provide reliability and performance on the engine or transmission, under the hood, on the chassis, or in the cab.

|

| Key Features

|

|

- Integral connector latch

- Rugged thermoplastic housing

- -55°C to +125°C operating temperature

- Available in 2, 3, 4, 6, 8 & 12 sizes

- Silicone seals, Accepts AWG 18 through 14 wire

|

- Crimp contacts with option of gold or nickel, solid or stamped

- Current rating: 13A all contacts, Hand insertable/removable contacts

- 1500V, 20G @ 10 to 2000HZ, IP 67 to IP 6K 9K

- Budget-minded

|

|

Performance Specs

- Operating Temperature: -55°C to +125°C continuous at rated current operating temperature

- Durability: 100 cycles of engagement and disengagement with no electrical or mechanical defects

- Vibration: After sinusoidal vibration levels of 20G's at 10-2000Hz in each of the 3 mutually perpendicular planes:

- No unlocking or unmating

- Exhibits no mechanical or physical damage

- No electrical discontinuities longer than 1 microsecond

- MIL-STD 202, Method 213, Condition "C" Physical Shock: During, or after, 50G's in each of three mutually perpendicular planes:

- No unlocking, unmating, or other unsatisfactory result

- No electrical discontinuities longer than 1 microsecond.

- Fluid Resistance: Connectors show no damage when exposed to most fluids used in industrial applications

- Insulation Resistance: 1000MΩ minimum at 25°C

- Moisture Resistance: Properly wired and mated connections withstand immersion under three feet of water without loss of electronic qualities or leakage

- Dielectric Withstanding Voltage: Current leakage less than 2mA at 1500VAC

- Thermal Cycle: No cracking, chipping or leaking after 20 test cycles from -55°C to +125°C

|

|

TE Connectivity / DEUTSCH DTM Series Connectors

TE Connectivity / DEUTSCH DTM Series Connectors feature

a miniature contact with an enhanced design based on the world class,

field-proven DEUTSCH "DT" Series. The DTM is designed for use in harsh

environmental applications where reliable signal circuits are critical

to operating performance. Typical applications include on or around the

engine, the transmission, and under the hood. TE Connectivity / DEUTSCH

DTM Series connectors provide peak connector performance everywhere data

signals or critical electronic circuits are needed.

|

Key Features

|

- Rugged thermoplastic housing

- Integral connector latch

- -55C to +125C operating temperature

- Available in 2, 3, 4, 6, 8 & 12 contact arrangements

- Silicone seals , Accepts AWG 16 through 24 (1.0mm2 to 0.2mm2)

- Crimp contacts with option of gold or nickel finish, solid or stamped construction

- Current rating 7.5 Amps all contacts @ 125C continuous

|

- Hand insertable/removable contacts

- Budget-minded

- 1500V, IP 67 to IP 6K 9K, 20G @ 10 to 2000 HZ

- Dielectric withstand

- Sealing range

- Temp range

- Vibration

|

|

Performance Specs

- Operating Temperature: -55°C to +125°C continuous at rated current operating temperature

- Durability: 100 cycles of engagement and disengagement with no electrical or mechanical defects

- Vibration: After sinusoidal vibration levels of 20G's at 10-2000Hz in each of the 3 mutually perpendicular planes:

- No unlocking or unmating

- Exhibits no mechanical or physical damage

- No electrical discontinuities longer than 1 microsecond

- MIL-STD 202, Method 213, Condition "C" Physical Shock: During, or after, 50G's in each of three mutually perpendicular planes:

- No unlocking, unmating, or other unsatisfactory result

- No electrical discontinuities longer than 1 microsecond.

- Fluid Resistance: Connectors show no damage when exposed to most fluids used in industrial applications

- Insulation Resistance: 1000MΩ minimum at 25°C

- Moisture Resistance: Properly wired and mated connections withstand immersion under three feet of water without loss of electronic qualities or leakage

- Dielectric Withstanding Voltage: Current leakage less than 2mA at 1500VAC

- Thermal Cycle: No cracking, chipping or leaking after 20 test cycles from -55°C to +125°C

|

|

TE Connectivity / DEUTSCH DTP Series Connectors

TE's DTP Series connectors are the answer to all of your most demanding power application requirements. DTP Series connectors offer the proven reliability and quality of TE's DT Series, combined with the added flexibility of using power contacts.

The DTP Series offers the designer the ability to use multiple size 12 contacts, each with a 25 amp continuous capacity, within a single shell. The DTP connectors are currently available in two and four pin configurations.

|

| Key Features |

|

- 1 bar pressure

- From -55C to +200C

- Altitude sealing

- Aerospace fluids resistant

- From 48h to 500h salt spray

- Aluminum or stainless steel body

|

- Compacity

- Weight saving

- Many arrangements existing

- Cost saving

- 10-14 AWG

- 2 and 4 Cavity arrangements

|

|

Performance Specs

- Operating Temperature: -55°C to +125°C continuous at rated current operating temperature

- Durability: 100 cycles of engagement and disengagement with no electrical or mechanical defects

- Vibration: After sinusoidal vibration levels of 20G's at 10-2000Hz in each of the 3 mutually perpendicular planes:

- No unlocking or unmating

- Exhibits no mechanical or physical damage

- No electrical discontinuities longer than 1 microsecond

- MIL-STD 202, Method 213, Condition "C" Physical Shock: During, or after, 50G's in each of three mutually perpendicular planes:

- No unlocking, unmating, or other unsatisfactory result

- No electrical discontinuities longer than 1 microsecond.

- Fluid Resistance: Connectors show no damage when exposed to most fluids used in industrial applications

- Insulation Resistance: 1000MΩ minimum at 25°C

- Moisture Resistance: Properly wired and mated connections withstand immersion under three feet of water without loss of electronic qualities or leakage

- Dielectric Withstanding Voltage: Current leakage less than 2mA at 1500VAC

- Thermal Cycle: No cracking, chipping or leaking after 20 test cycles from -55°C to +125°C

|

|

TE Connectivity / DEUTSCH DTHD Series Connectors

The DEUTSCH DTHD Series Power Plugs are single terminal connectors developed for applications requiring a complete, environmentally sealed, single power circuit termination. The plug features an integral coupling latch that provides tactile and audible feedback during coupling.

The rugged thermoplastic receptacle is designed as an inline for cable-to-cable applications and is supplied with an integral Vee-Groove to accept mounting clips, brackets and flanges. Crimp-type solid contact sizes 4, 8 and 12 accept wire sizes AWG 6, AWG 8, AWG 10, AWG12 and 14 respectively.

|

|

Key Features

|

|

- Current leakage less than 2mA at 1500 VAC.

- Operating at temperatures from -55C + 125C.

- Accepts contact sizes 4 (100 amps), 8 (60 amps), and 12 (25 amps)

- 6-14 AWG

|

- 1 cavity arrangement

- In-line or flange mount

- Circular, thermoplastic housing

- Integrated latch for mating

|

|

Performance Specs

- Operating Temperature: -55°C to +125°C continuous at rated current operating temperature

- Durability: 100 cycles of engagement and disengagement with no electrical or mechanical defects

- Vibration: After sinusoidal vibration levels of 20G's at 10-2000Hz in each of the 3 mutually perpendicular planes:

- No unlocking or unmating

- Exhibits no mechanical or physical damage

- No electrical discontinuities longer than 1 microsecond

- MIL-STD 202, Method 213, Condition "C" Physical Shock: During, or after, 50G's in each of three mutually perpendicular planes:

- No unlocking, unmating, or other unsatisfactory result

- No electrical discontinuities longer than 1 microsecond.

- Fluid Resistance: Connectors show no damage when exposed to most fluids used in industrial applications

- Insulation Resistance: 1000MΩ minimum at 25°C

- Moisture Resistance: Properly wired and mated connections withstand immersion under three feet of water without loss of electronic qualities or leakage

- Dielectric Withstanding Voltage: Current leakage less than 2mA at 1500VAC

- Thermal Cycle: No cracking, chipping or leaking after 20 test cycles from -55°C to +125°C

|

|

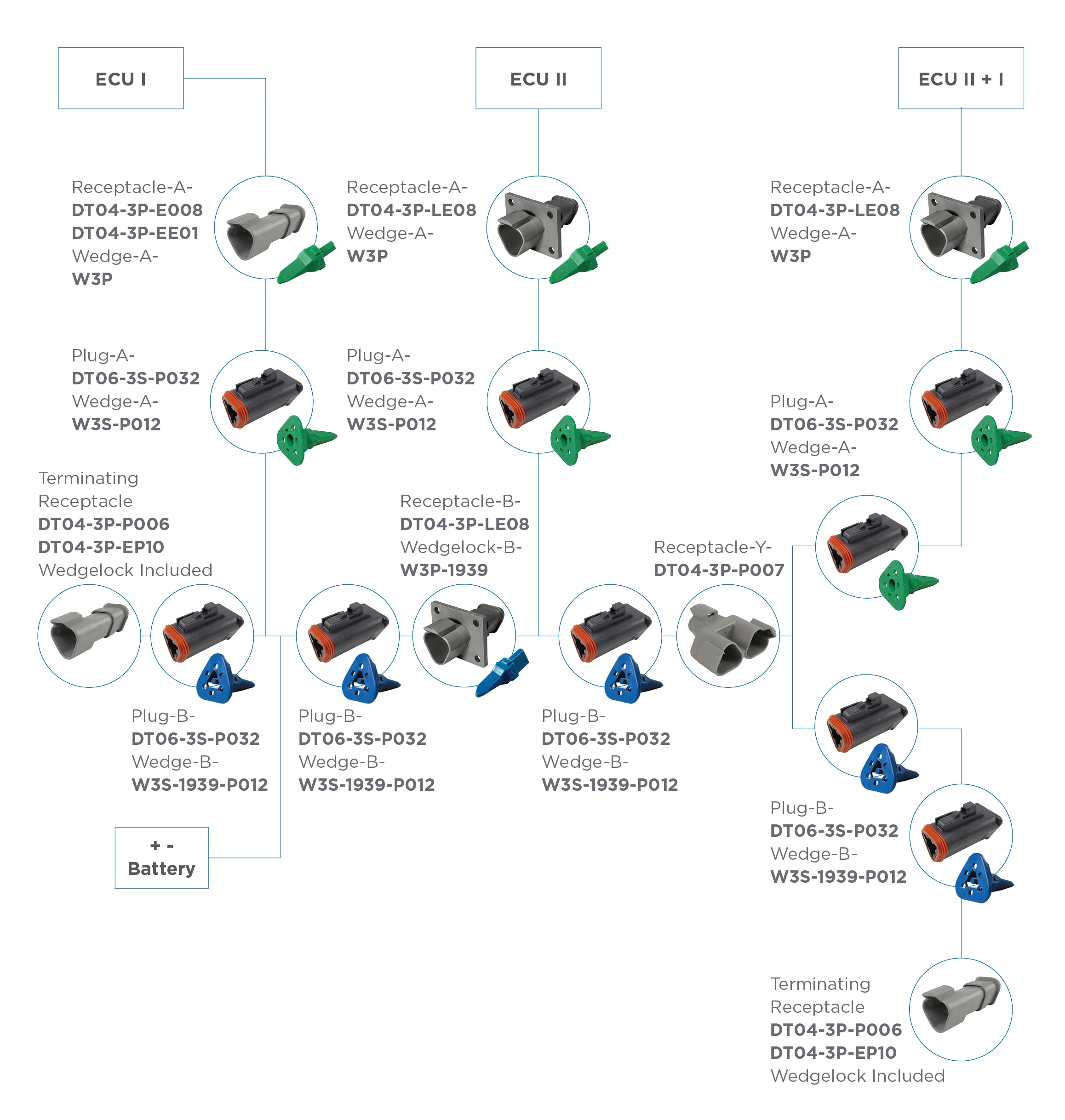

TE Connectivity / DEUTSCH SAE J1939/11 Connectors & Components

TE Connectivity / DEUTSCH J1939/11 compliant DT Series connectors are rugged field proven DT 3-pin connectors designed to meet the SAE requirements for 3-wire CAN applications linking ECUs for serial data communications. The DT 3 way connectors accommodate the CAN_HI, CAN_LO, and shield wires with a variety of options, including:

- "Y" receptacles

- Connectors with mounting flanges

- Keyed wedgelocks to prevent mismating

- Network terminating connectors with molded-in 120Ω resistors

|

|

J1939/11 Parts Chart

|

|

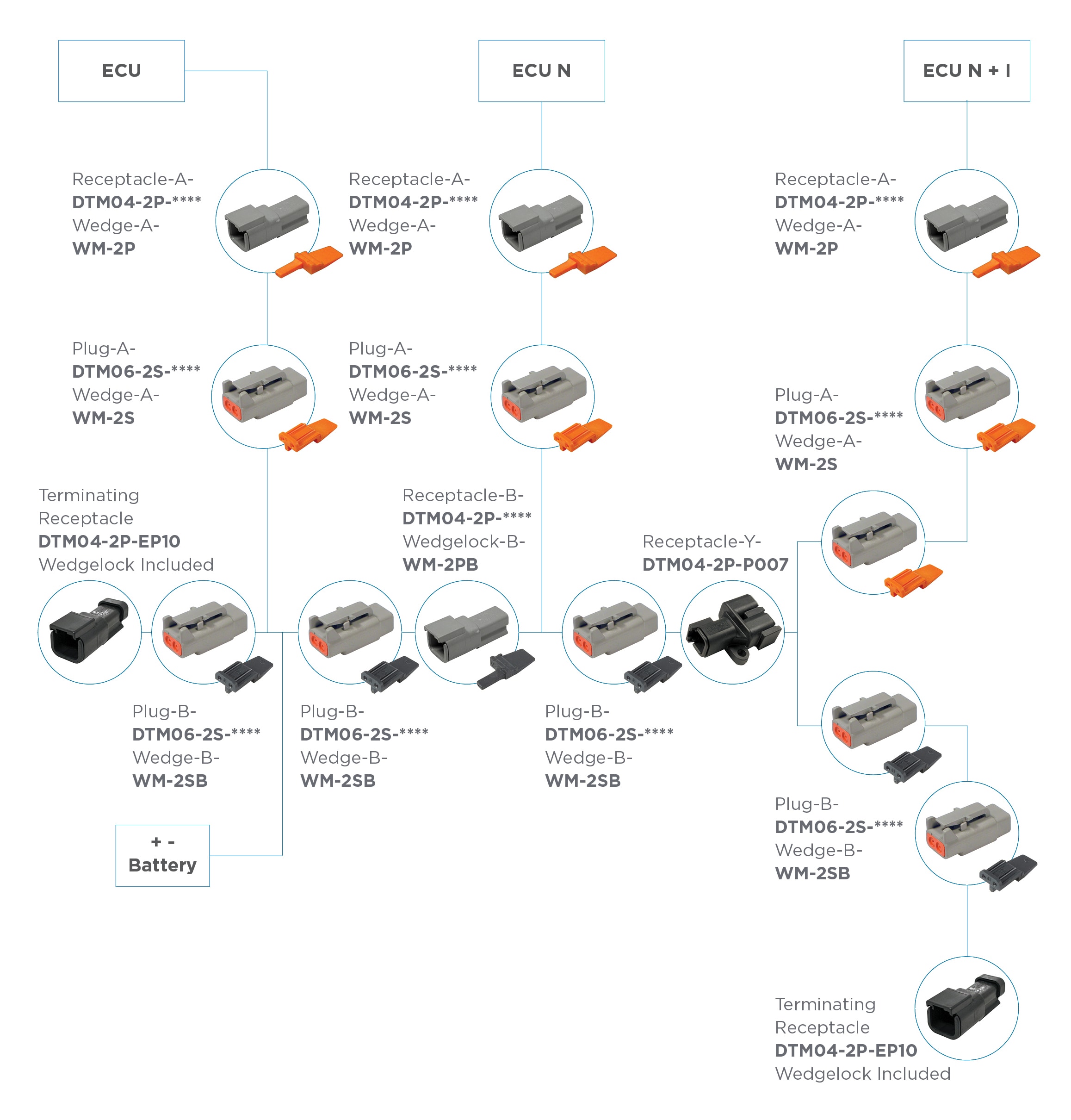

TE Connectivity / DEUTSCH SAE J1939/15 Connectors & Components

TE Connectivity / DEUTSCH DTM 2 way connectors are offered in several modifications to meet the requirements of the SAE J1939/15 standard. DTM connectors for serial data communications include:

- "Y" receptacles

- Connectors with end caps and shrink book adapters

- Receptacles with molded-in 120Ω resistors for network terminations

|

J1939/15 Parts Chart

|

TE Connectivity / DEUTSCH DT Detector

TE Connectivity / DEUTSCH DT Detector is an extension of the DT connector series. The 2 way plug features a transparent housing and a wedgelock with an integrated 12 or 24V LED option. The environmentally sealed Detector plug provides a visual confirmation of power to help with troubleshooting, especially in areas with difficult connector visibility and accessibility.

|

Features

- Integrated LED circuit on the wedgelock

- Accepts all size 16 DEUTSCH contacts, solid or stamped & formed

- Multi-directional viewing of LED through transparent housing

- Color coded wedgelocks for operating voltages, 12VDC (yellow) and 24VDC (red)

- Joint retention fingers allow both contacts to be removed at the same time

- Compatible with pulse width modulated control

|

Performance Specifications

- -55°C to +125°C operating temperature

- 13A contact current rating

- Flammability rating: UL94-V0 rated housing material, UL94-JB rated seal material

- Category: IP67, IP6K9K when used with backshells

- LED Circuit Current: Two LED circuit with operating current of ~10mA

- Vibration: No unlocking or unmating and exhibits no mechanical or

physical damage after sinusoidal vibration levels of 20 G's at 10 to

2000Hz in each of the three mutually perpendicular planes. No electrical

discontinuities longer than 1 microsecond

|

|

TE Connectivity / DEUTSCH DT Family Accessories / Tooling

TE Connectivity / DEUTSCH DT Family Accessory / Tooling items are available to complement the DT Family of connectors including boots, backshells, gaskets, dust caps, and mounting clips. Accessory items cover a wide array of design requirements such as assisting with moutning, providing additional protection, and offering enhanced aesthetics.

|

| Accessory |

Details |

View DT |

View DTM |

View DTP |

| Secondary Wedgelocks |

DEUTSCH DT style electrical connectors require secondary wedgelocks. These wedgelocks help confirm proper contact alignment within each connector. Secondary wedgelocks are assembled at the mating interface and press into place. If the secondary wedgelocks are somehow not properly seated during assembly, they will be pressed into locked position during the mating of the connector. Adding to the design flexibility of the DT series, several wedgelocks offer keying options. Wegelocks for enhanced seal retention plugs (P012) are also available.

|

View Product List View Product List

|

View Product List View Product List

|

View Product List View Product List

|

| Gaskets |

Moisture, dirt, salt, sand, and road debris can work their way into electrical panels through unsealed mounting flanges. Rated to operate in environments from -70ºF to +225ºF (-56ºC to +107ºC), these rugged, high quality, neoprene gaskets form a tight seal between the panel face and connector flange to help keep out destructive elements. The gaskets have a thickness of .125" and the material meets the UL-94-HBF, Mil-R-6130C, and FMVSS-302 flammability specifications.

|

View Product List View Product List

|

View Product List View Product List

|

View Product List View Product List

|

| Dust Caps |

The DT Series dust caps are made of either thermoplastic or durable plastisol. The dust caps are designed to provide protection for the connector interface when the two halves are not mated. The plastisol caps, available for plugs and receptacles, are suitable for providing temporary protection from dirt, dust, and paint overspray. The thermoplastic caps provide an environmental seal for an unmated plug.

|

View Product List View Product List

|

View Product List View Product List

|

-

|

| Boots |

Boots provide a professional looking finishing touch for DEUTSCH DT family connectors. The slip-on boots are made of durable plastisol and provide increased protection from dirt, paint overspray, and pressure washing while providing an appealing aesthetic. The plastisol boots are rated from -20ºF to +212ºF (28ºC to +100ºC) and offer a slip-on design making installation quick and easy.

|

View Product List View Product List

|

-

|

View Product List View Product List

|

| Backshells |

The DEUTSCH DT and DTM Series backshells are designed to snap onto and mate with all standard (base plug and receptacles without modifications that affect the rear of the connector) DT and DTM series connectors. The rigid, durable backshells offer a high level of protection and allow convoluted tubing to nest within the rear of the backshell.

Straight (180º) and right angle (90º) versions and backshells with straing relief for jacketed cable are also available. Since the backshells are designed to work with the standard DT and DTM connectors, tests should be conducted for fit and fucntion of a backshell being used on any part with a modification.

|

View Product List View Product List

|

View Product List View Product List

|

-

|

| Mounting Clips |

Mounting clips are installed on the receptacle to mount DT series connectors. To meet design needs, the clips are available for several configurations and in plastic, stainless steel, or steel with zinc plating.

|

View Product List View Product List

|

View Product List View Product List

|

View Product List View Product List

|

|

|

The two types of DEUTSCH contacts are solid and stamped & formed. Both styles of contacts are designed for crimp style terminations - no solder is required or recommended. Several tools are available for hand wire crimping and wire insertion

and removal. The tools are specific to the solid contacts or the stamped

& formed contacts. To create a proper crimp and achieve the highest

performance specifications, contacts must be crimped with the

recommended tooling.

| Tooling |

Description |

View Solid Contacts |

View Stamped & Formed Contacts |

| Hand Tools |

TE Connectivity / DEUTSCH offers several easy-to-use hand crimp tools for both solid barrel and stamped & formed contacts. All hand crimp tools provide a tight, complete crimp with minimal effort.

The HDT-48-00, the most commonly used tool for solid contacts, crimps a wide range of contact sizes. It provides a symmetrical four indent crimp, is compact and easy-to-use for field service, yet sturdy and reliable enough for low volume production.

Hand crimp tools for DEUTSCH stamped & formed contacts are wire gauge specific and simultaneously crimp the insulation and conductor, saving time and effort during field service.

|

View Product List View Product List

|

View Product List View Product List

|

| Tooling Accessories |

Additional accessories are available to aid in the removal of contacts, wedgelocks, and to check for proper calibration.

|

View Product List

|

|

|

Bulgaria

Bulgaria