ATI Industrial Automation QC-76 Robotic Tool Changers

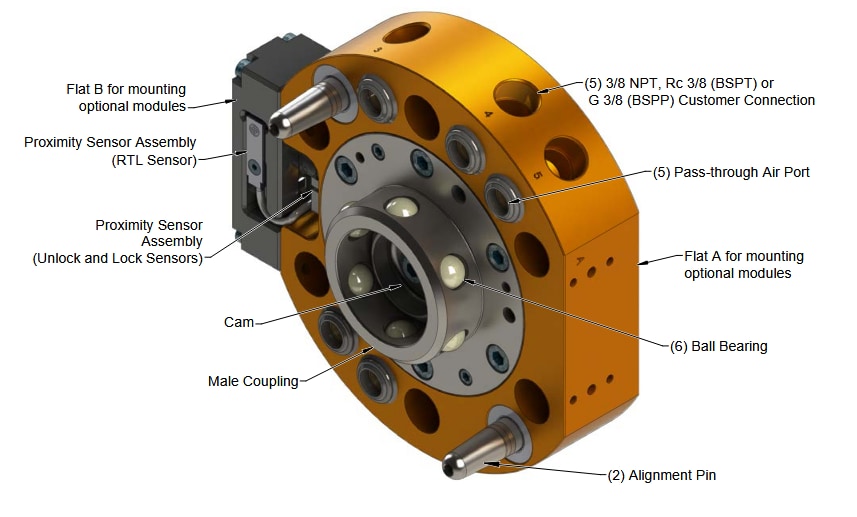

ATI Industrial Automation QC-76 Robotic Tool Changers feature a lightweight design with high strength. The No-Touch Locking technology allows up to 2.0mm plate separation when locking. The QC-76 also includes a Fail-Safe locking mechanism that results in low force acting on the piston. ATI Tool Changers enhance a robot's versatility by enabling multiple tools, such as grippers, vacuum cup tooling, pneumatic/electric motors, weld guns, and more.Features

- Lightweight design with high strength

- Up to 2.0mm plate separation when locking with No-Touch Locking technology

- Fail-Safe locking mechanism design results in low force acting on the piston

- Five connections for passing air or vacuum through the Tool Changer

- Two connections are available to supply pneumatic pressure for coupling and uncoupling the Tool Changer

- Internal proximity sensors are designed into the body of the Master plate to verify the lock/unlock position of the piston and cam - sensors provide the lock and unlock (L/U) signals through the provided sensor cables

- Two flats available for mounting of J16 pattern modules for support of various utility pass-through, such as signal, fluid/air, and power (other modules may be mounted with adapter plates)

Specifications

- 100kg suggested payload limit

- 12,000N locking force at 80psi (5.5bar)

- 542Nm static moment capacity (x and y)

- 701Nm static moment capacity (z)

- 0.0152mm positional repeatability (x, y, and z)

- 3.67kg weight when coupled

- 2.03mm maximum distance between Master and Tool plates before locking at 87psi (6bar)

- Five 3/8 NPT pneumatic pass-through ports

3D CAD Models

Master Plate Assembly

Tool Plate Assembly

Published: 2025-07-16

| Updated: 2025-08-19